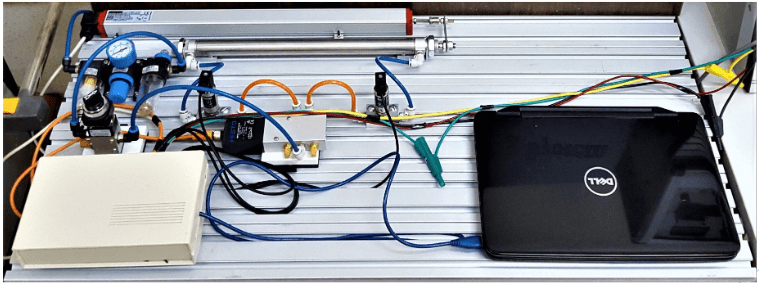

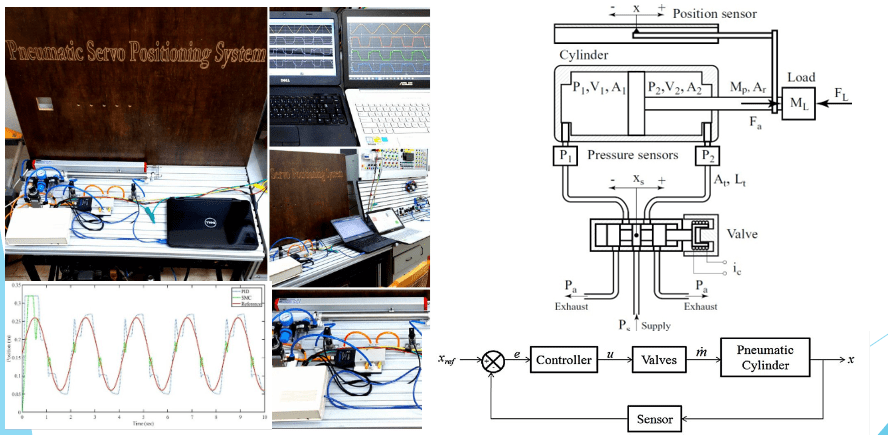

Servopneumatic system fault tolerant control project using sliding mode observer

Controlling the position of the servopneumatic system despite the failure of the valve, leaking pipes, or stuck operator arm The design of the sliding mode observer in order to increase the resistance against defects and failures and structural and non-structural uncertainties in the system.

Fault tolerant control to control the position of the pneumatic system when the operator fails

Designing anti-collapse and jamming system of electro-pneumatic actuators Improving the tracking and tracking of the reference position Increasing fault tolerance of an electro-pneumatic sample system

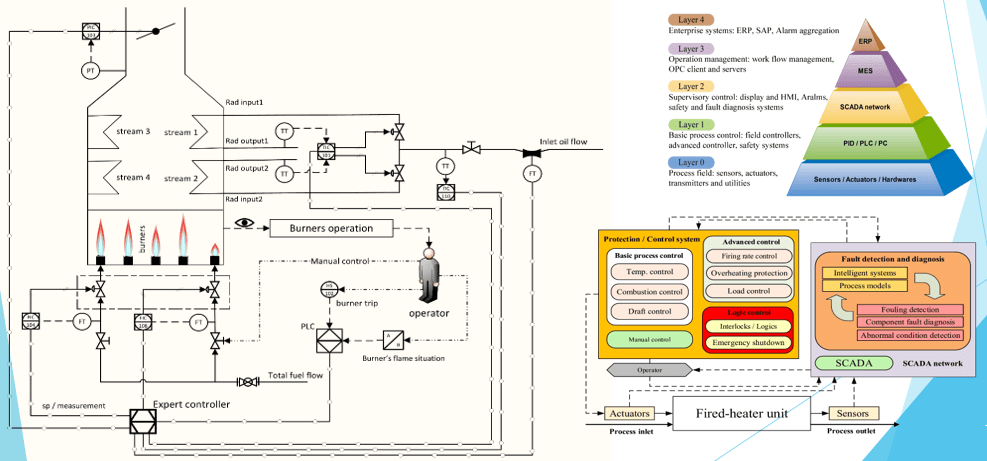

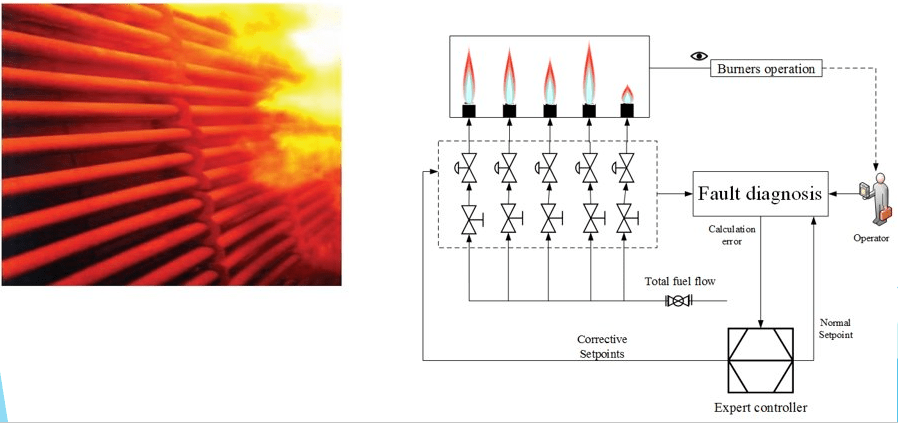

Designing a supervisory phase control system for process furnaces in one of the country’s refinery furnaces.

The designer of the protective system of process furnaces, including warnings, troubleshooting the combustion system, determining the state of clogging and the health of the pipes.

Designing a temperature control system to manage the abnormal conditions of the process furnace in one of the refinery furnaces of the country.

Designing a temperature control system to manage abnormal conditions in a type of crude oil preheating furnace Rearrangement of burners to compensate for the lost heat of the furnace

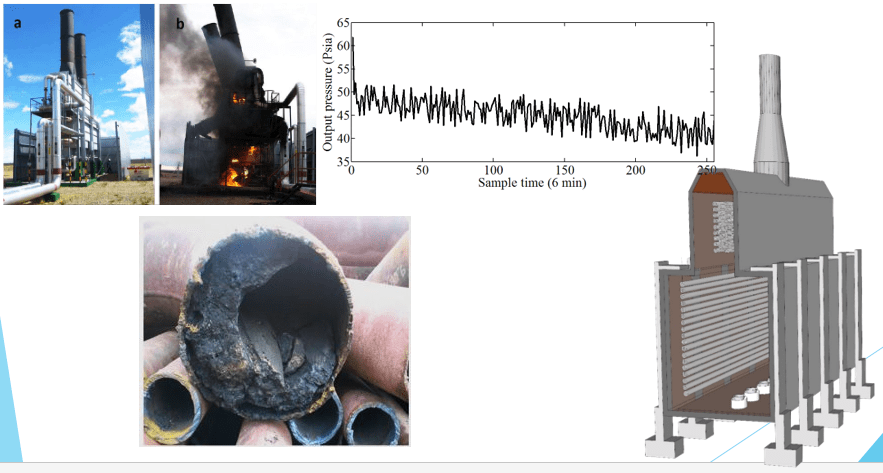

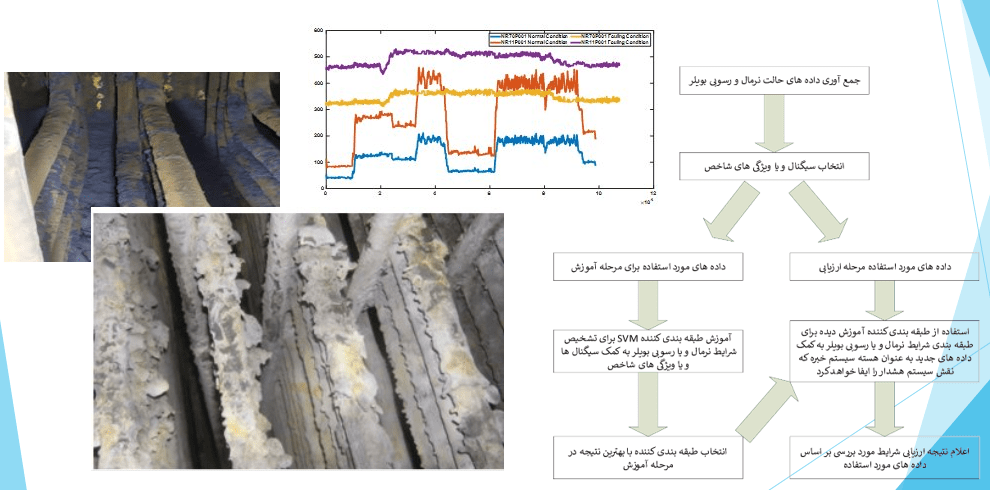

Modeling and troubleshooting of the crude oil preheating furnace in one of the country’s refineries (Iran’s National Petroleum Products Refining and Distribution Company)

Detection of clogging or fouling in refinery cabinet furnaces Determining the remaining life and estimating the time of complete blockage of the pipes to prevent the explosion of the furnace

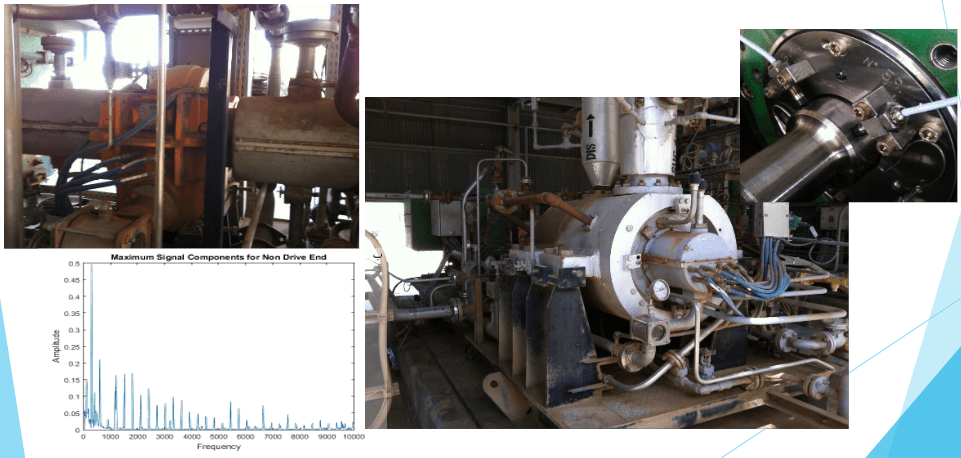

Identifying the fault of centrifugal gas compressors based on vibration analysis (National Iran Gas Company)

Diagnosing faults and determining the time for preventive repairs in high-speed compressors used in oil and gas industries.

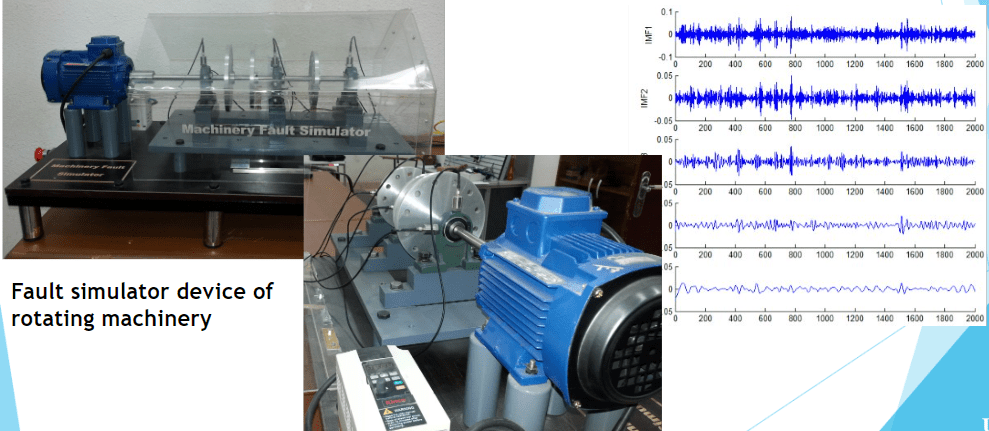

Vibration signal recovery in extreme noise conditions for rotating machine troubleshooting

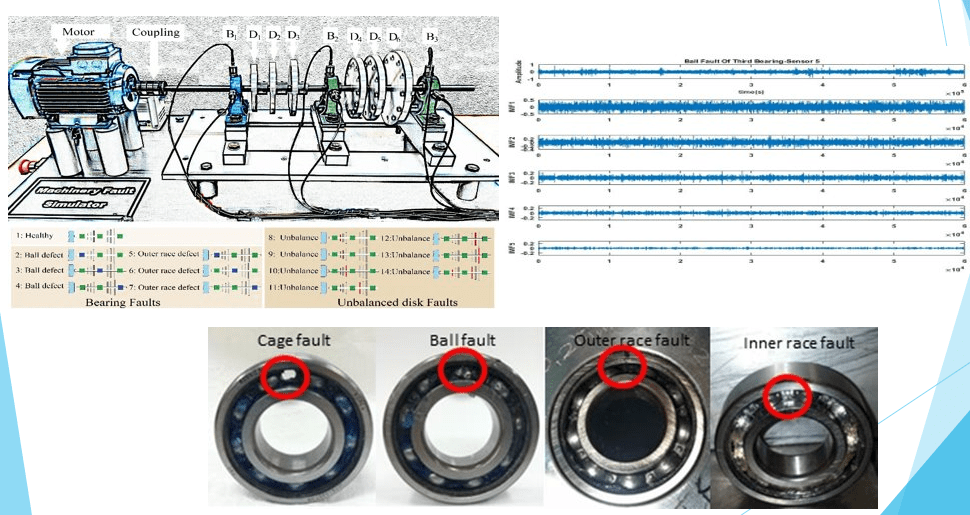

Diagnosing various types of faults in rotating machines, including combined bearing faults and unbalance in the presence of measured noise

Smart fault identification of rotating machines based on time-frequency analysis

Finding the position of the blade or broken parts without opening the casing or using borescope visual methods for turbines.

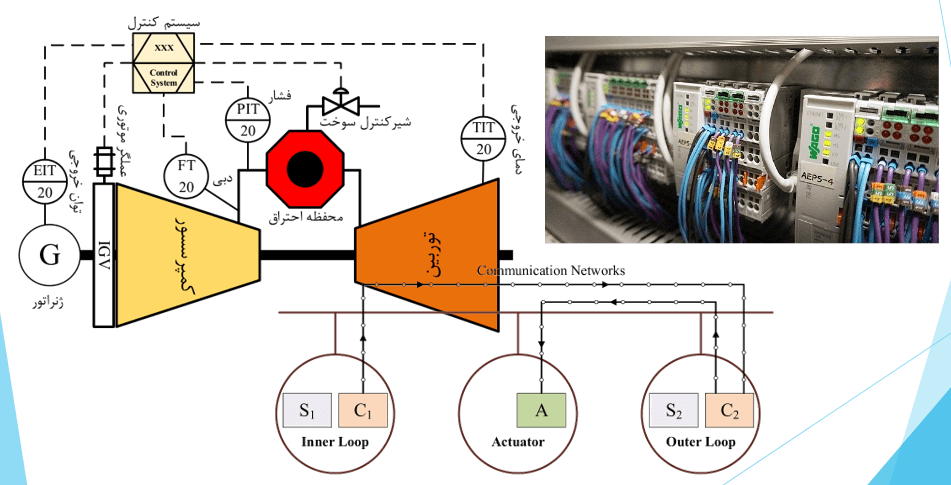

Designing a cascade control system under the influence of network delay and applying it to a power plant complex

Increasing the stability of control systems against data transmission delay or information loss in industrial networks (Mapna MGT-70-2 gas turbines)

Troubleshooting of steam power plant unit (steam unit of Shahid Salimi Neka power plant)

Designing an expert system for detecting the formation of sediment and soot on the external surfaces of the boiler of the steam unit based on the operating data available in the SCADA system. Investigating the methods of preventing and cleaning deposits of boiler thermal surfaces